DESINV 22: PROTOTYPING & FABRICATION

Our prompt for this midterm assignment was to create a drawing machine, defined only as a machine that leaves a mark on a surface. Working alongside the incredible Alina Rai, this was our finished result.

THE PRODUCT

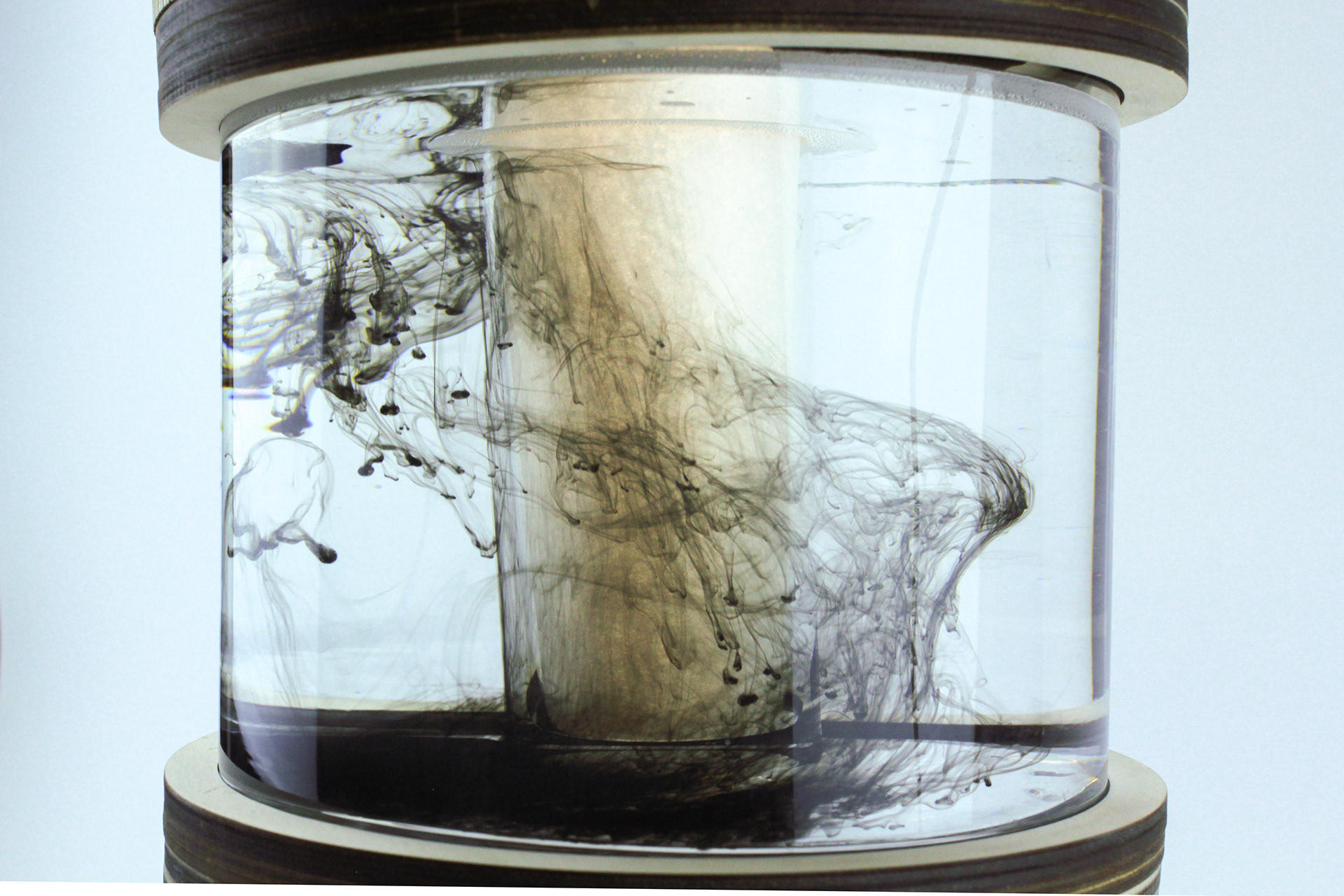

We designed a machine that approaches mark-making from a more abstract angle, and produces "drawings" by slowly dropping India ink into a water-based solution.

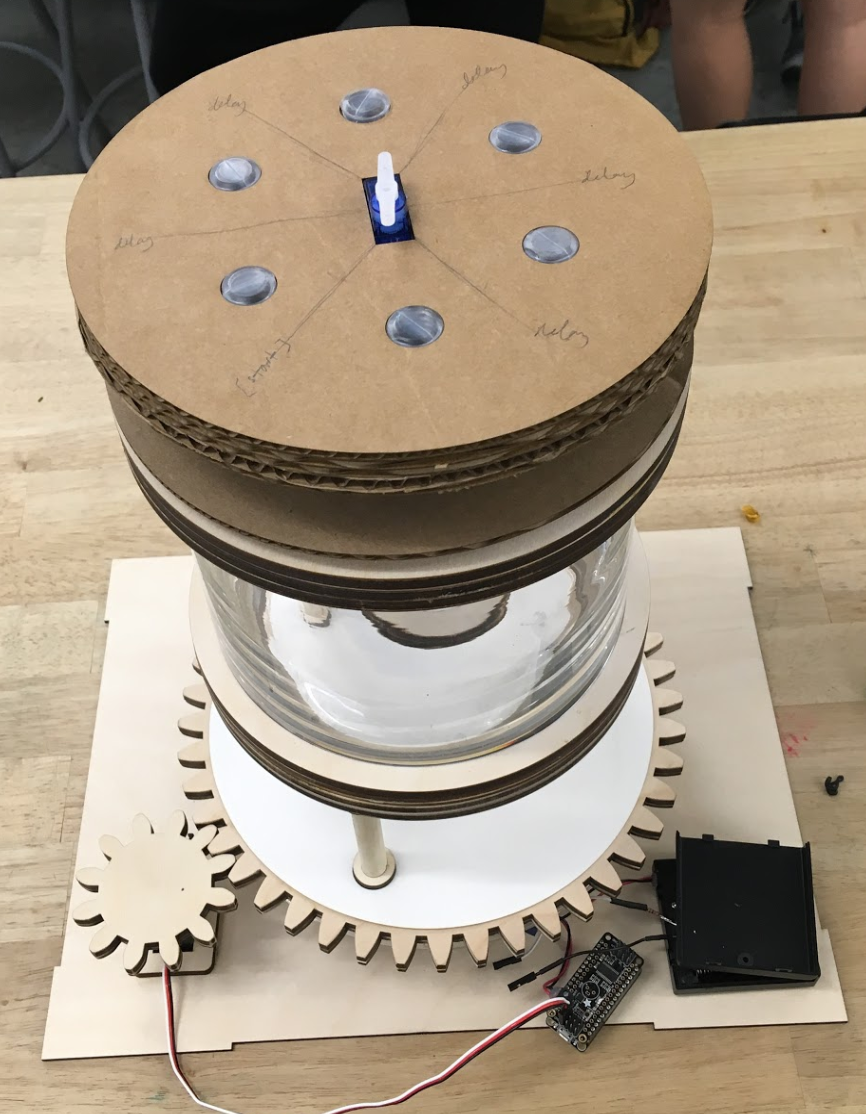

A roller controlled by a stepper motor moves at 60 degree angles to depress six pipettes arranged in a circle. As each pipette bellow is pressed, a single drop of ink descends into the water solution, which surrounds a pillar of light. The period between ink drips is about 1.5 minutes, allowing each ink droplet to fully unfurl and settle. As this occurs, the entire mechanism slowly spins -- though the water and ink inside remains stationary. Below are some of the evolutions of the "drawings" we were able to observe.

The Process

We had three weeks to iterate on our design. Along each step of the journey, we learned a tremendous amount and continued developing our ideas for the final product.

Out of all our initial ideas, we chose to work with liquid art because of its unpredictability and beauty. We began by experimenting with a range of liquid mixtures, from acrylic paint to glow-in-the-dark gel in water. After few tries, India ink looked like the best fit for the project, due to its slow and delicate movement.

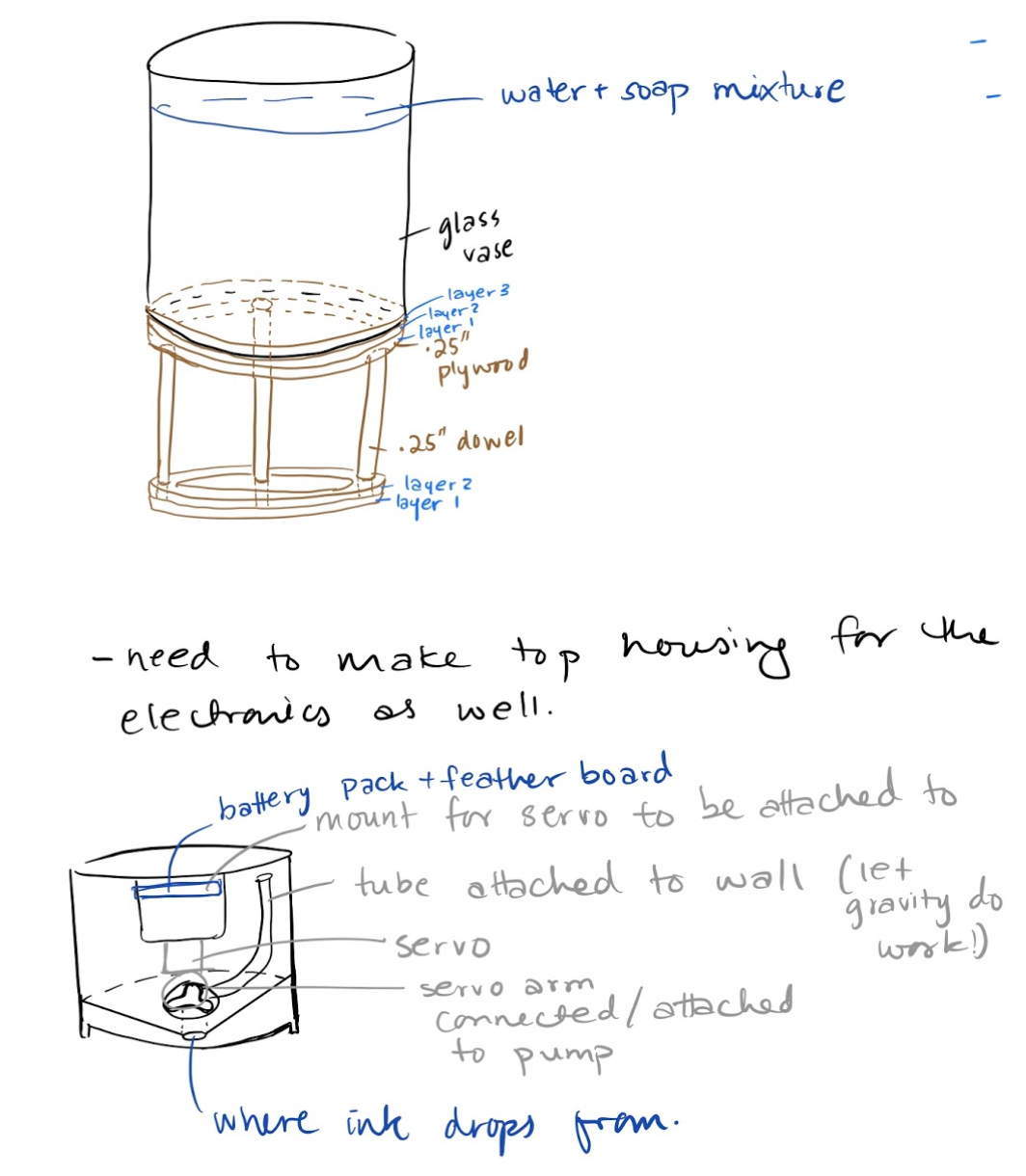

Perhaps the most challenging part was deciding how to mechanize the project. The two ideas that stood out the most were mechanizing the drops of ink (solute) that would be going into the water and soap mixture (solvent), and/or mechanizing the base itself to rotate using a continuous servo as seen in the images above. We immediately thought that slowly rotating the base could be a delightful way to highlight that the liquid inside actually remains inert. To mechanize the droplets, we considered using a peristaltic pump for better speed control or 3D printed nozzles for volume control. With these possibilities in mind, we set out on a range of experiments (of varying complexity) to mechanize the ink drip top. Our first thought was to have the drip appear to be entirely random by having it move along an organically shaped track (shown to the left). When this proved too technically complex, we switched to the idea of a roller mechanism. While the roller’s motion would not be entirely random, it would move very slowly to depress the bellows of six pipettes around a circle.

From there, we focused our attention on building out the housing and circuitry, and constructed a living hinge (with exit points for a switch and the cable) to wrap around the top and hide the circuitry. However, the design leaves the roller and the wheels open to view, to give audiences a peek into the mechanism at work. Similarly, a clean simple box hides the rotating gears and servo underneath the vase, but sits just high enough above the gear to still allow for a hint of the rotation to show through. As a final touch, we installed another smaller vase in the center of the machine, in which a warm diffused light would provide a subtle background to the ink drawings.

NEXT STEPS

Though we spent most of our time iterating on this, one of the biggest problems we experienced remained getting the ink to drip at the correct volume. For future iterations, we would consider how to devise a system that, when pushed, could better control how much ink escaped the pipette at once. In addition, the construction of the top did not allow for easy refilling of the pipettes, which had to be taken out one by one and replaced. While testing this with water, the refilling was fairly simple. Yet, the process was understandably much messier with ink. It would also have been great to eliminate the wire coming from the top of the mechanism, and replace this with a battery to feed the feather. If this was to be replaced, we would also need to spend some time thinking about how the code “restarts” the mechanism after reaching the desired six 20 degree-sweeps along the pipettes. Finally, in a more ambitious vein, we also wonder if it would be possible to pump and filter the water continuously.